- CARGO-2000

(RADAR) - CARGO-2000

(MAGNETIC) - VIP 2000

- HAI-2000

- BAL-2000

(PURE PNEUMATIC) - BAL-2000

(ELECTRO PNEUMATIC) - BAL-2000

(ELECTRIC PRESSURE)

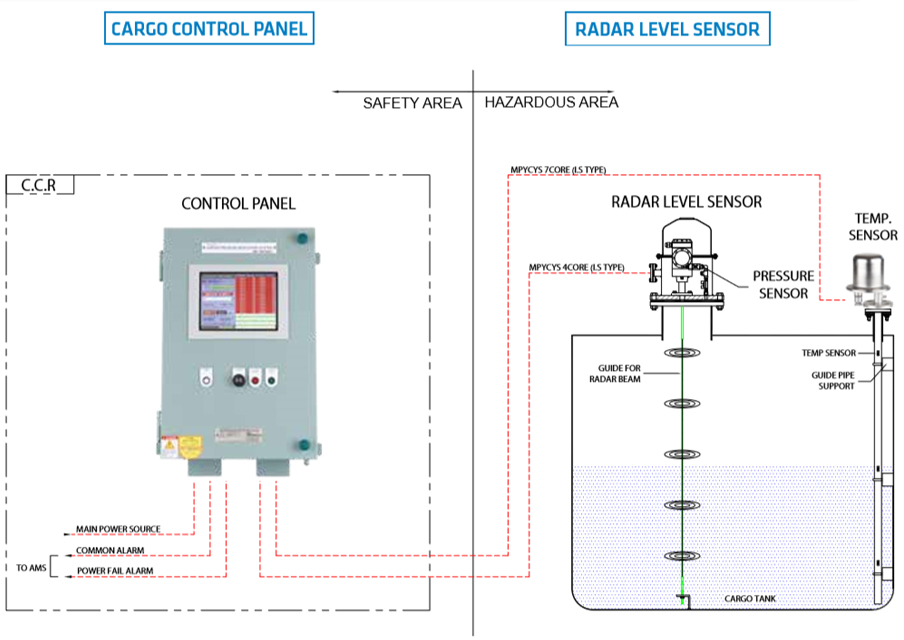

GARGO TANK MONITORING SYSTEM - LEVEL CARGO-2000( RADAR TYPE )

GENERAL INFORMATION

RADAR TYPE CARGO TANK MONITORING SYSTEM is basically designed to measure the liquid/solid level of cargo tanks from CCR. This system uses two types of radar sensors; Radar beam type sensor using non-contact measurement with the objects and Guided wire type radar sensor protecting the radar impulse by guided wire. This system is designed according to the Rule of Classification Society, 46 CFR part 39.20-3. And ExxonMobil MESC 2010 Requirements.OPERATION PRINCIPLE & SYSTEM COMPOSITION

CARGO-2000 is composed of radar sensors for measuring the level, control panel for monitoring the measured value by touch LCD and barrier for ex-proof. RADAR BEAM TYPE SENSOR uses FMCW(frequency modulated continuous wave) electromagnetic signal to measure the distance between its antenna and the cargo tank’s content surface. GUIDED WIRE TYPE RADAR SENSOR uses the TDR principle. Radar impulses are emitted to the product surface and the sensor measures the time of the reflected impulses. Then sensor can measure the level by calculating the time and the speed of impulses.

- FEATURE & ADVANTAGE

- High accuracy / Proper price

- Easy maintenance

- Alternative to pressure type & float type

- Non contact measurement

- Touch screen / Easy operation

- Measure for both liquid and solid

- APPLICATION

- All kinds of oil & chemical tankers

COMPONENTS / OUTLINE

TECHNICAL SPECIFICATION

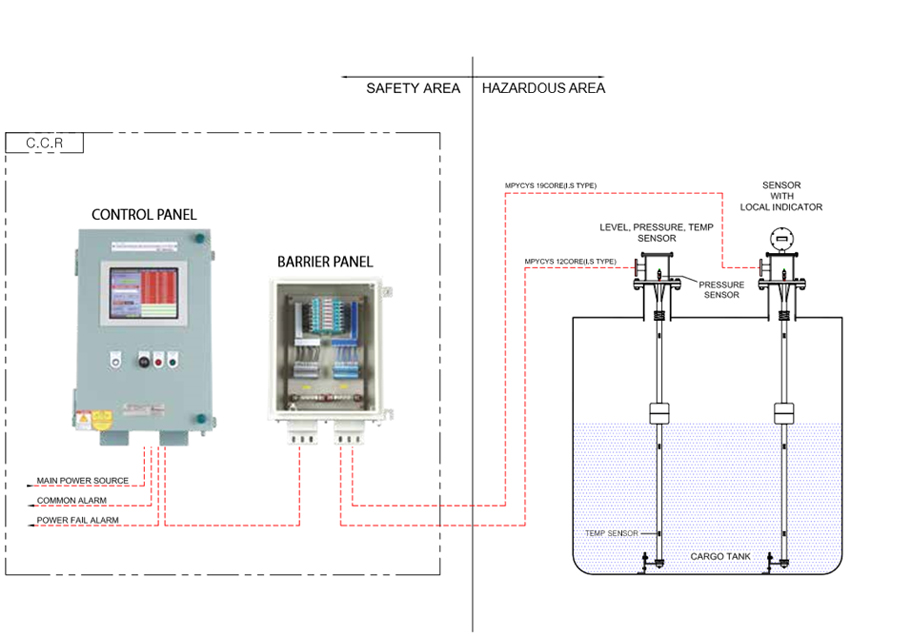

GARGO TANK MONITORING SYSTEM - LEVEL CARGO-2000 ( MAGNETIC )

GENERAL INFORMATION

MAGNETIC FLOAT TYPE CARGO TANK MONITORING SYSTEM is basically designed to measure the level inside cargo tanks and occur alarms when the measured value exceeds the limit. This system uses float type level sensors. Our magnetic float level sensor has been developed based on the long time of the marine field experience and its performance and stability are proved already. This system is designed according to the Rule of Classification Society, 46 CFR part 39.20-3.OPERATION PRINCIPLE & SYSTEM COMPOSITION

CARGO-2000 is composed of float sensors for measuring the level, control panel for monitoring the measured value by touch LCD and barrier for ex-proof. Sets of reed switches are positioned along the length of the guide pipe. As the float travels up and down the guide pipe in accordance with the level of the liquid in the tank, the flux emitted from magnets within the float works upon the reed switches ON or OFF. By measuring voltage across the transmitter circuit, the level of the liquid can be calculated according to the changes in circuit resistance. The converted signal is sent to the control box via I.S. barrier in the control room or to a local indicator as the case may be.

- FEATURE & ADVANTAGE

- Proper price

- Simple structure

- Easy maintenance and repair

- Contact measurement

- Touch screen / easy operation

- Measure for liquid

- APPLICATION

- All kinds of oil & chemical tankers

COMPONENTS / OUTLINE

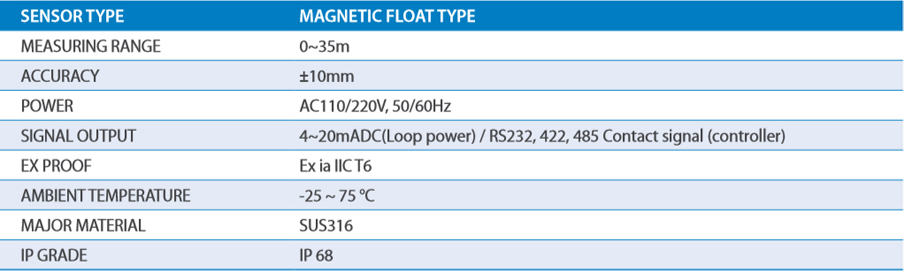

TECHNICAL SPECIFICATION

GARGO TANK MONITORING SYSTEM - LEVEL VIP 2000

GENERAL INFORMATION

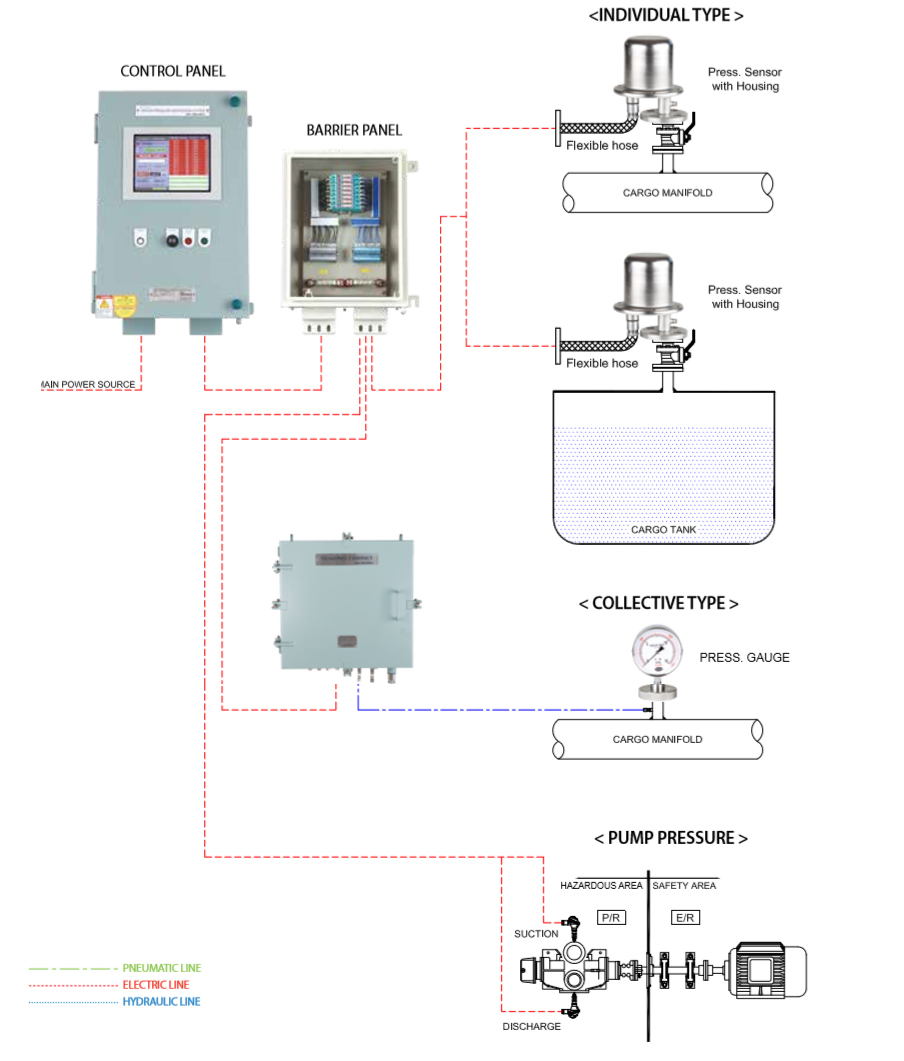

PRESSURE MONITORING SYSTEM is designed for monitoring the pressure of cargo tank or manifold. The Rules that cargo tanks ullage space monitoring system including high & low pressure alarm are newly required by IMO Regulation 59, SOLAS regulation Ⅱ.6.3.2 & IACS SC140 for preventing the serious deformation of the tank structure caused by change of cargo tank pressure due to the failure of the P/V valve.OPERATION PRINCIPLE & SYSTEM COMPOSITION

VIP-2000 is composed of pressure transmitters, control panel for monitoring the measured value by touch panel and barrier for ex-proof. The transmitter measures the pressure by means of a semi-conductor sensor. The electrical signals from the pressure transmitter are connected to barrier. Then the signals are sent to the monitoring panel that is equipped with pressure alarm lamp & buzzer and LCD display in the cargo control room. If the owner wants to add the function for measuring temp., it is possible to add temp. sensor.

- FEATURE & ADVANTAGE

- High accuracy

- Possible to install regardless of the number of cargo tank

- Two types to monitor the pressure of tanks or manifolds (Individual type & Collective type)

- APPLICATION

- All kinds of oil & chemical tankers

COMPONENTS / OUTLINE

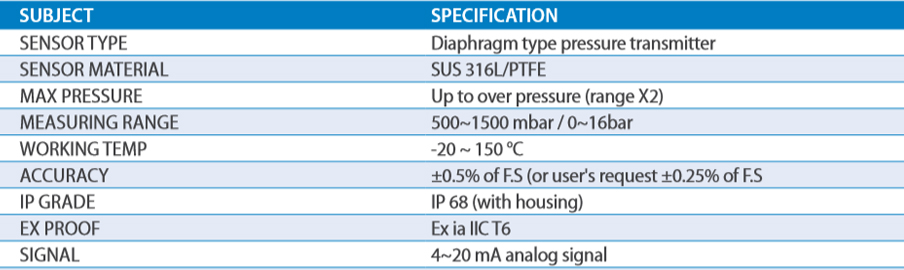

TECHNICAL SPECIFICATION

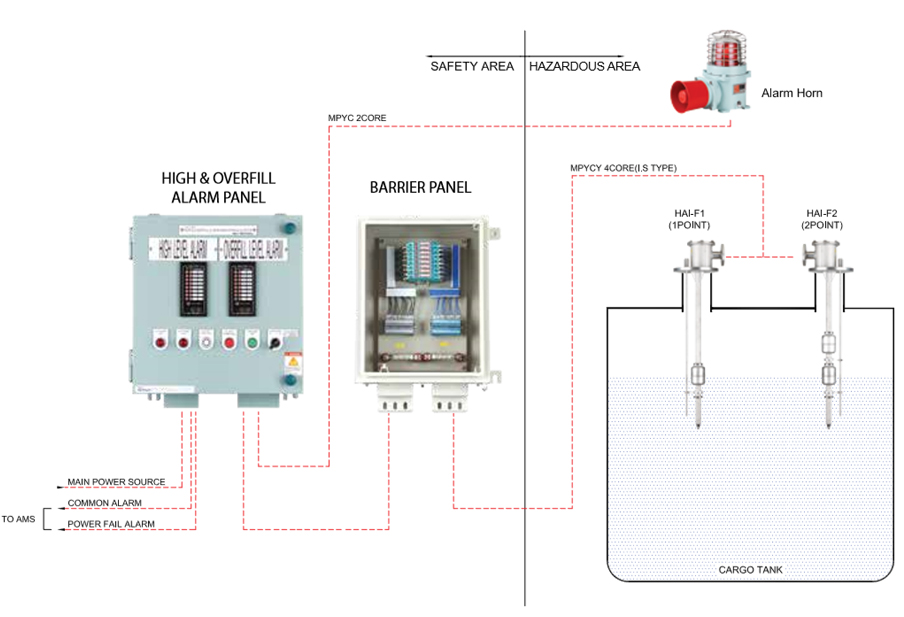

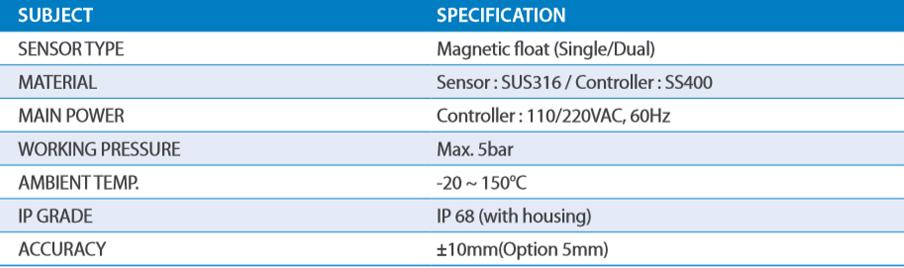

GARGO TANK MONITORING SYSTEM - LEVEL CARGO-HAI-2000 ( MAGNETIC FLOAT TYPE )

GENERAL INFORMATION

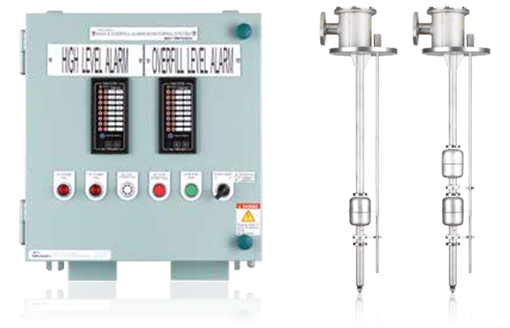

INDEPENDENT CARGO TANK HIGH/OVERFILL ALARM SYSTEM is designed to monitor cargo over flow when cargo tank is being loaded according to the rule of USCG (CFR 46 Part 39) and classification society. We can get audible and visual alarm when the cargo tanks are loaded at 95% and 98% of cargo tank.OPERATION PRINCIPLE & SYSTEM COMPOSITION

HAI-2000 is composed of magnetic float switches, a control panel, barriers and horns for the external alarm. When the liquid in the tank reaches a set point, the reed switch in the magnetic float moving up and down according to tank level makes signal and the controller receiving the signal makes audible and visual alarms.

- FEATURE & ADVANTAGE

- Compatible unit for all kinds of liquid

- High reliability, durability and simple structure

- APPLICATION

- All kinds of oil & chemical tankers

COMPONENTS / OUTLINE

TECHNICAL SPECIFICATION

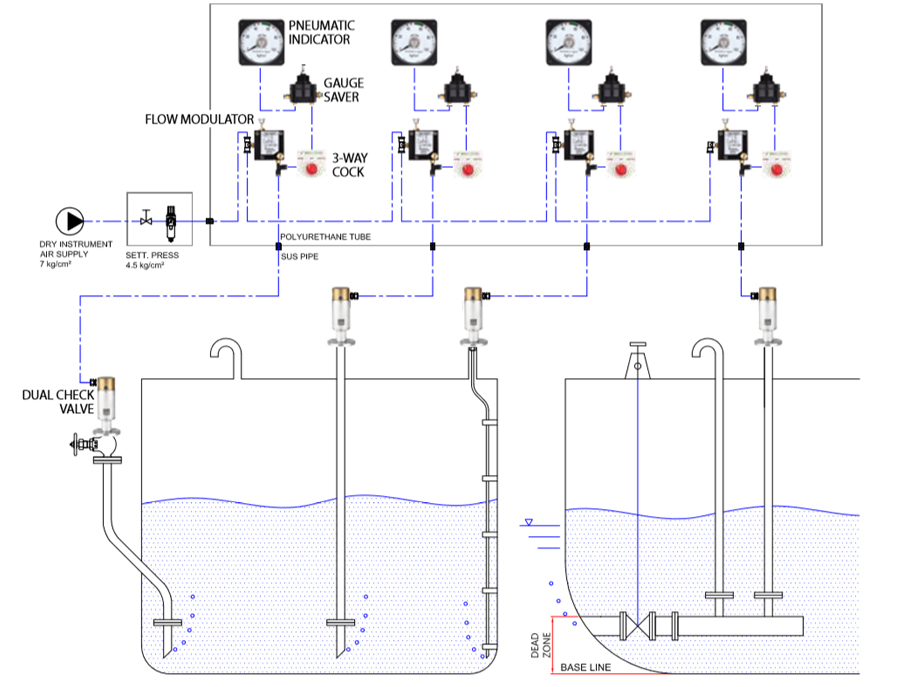

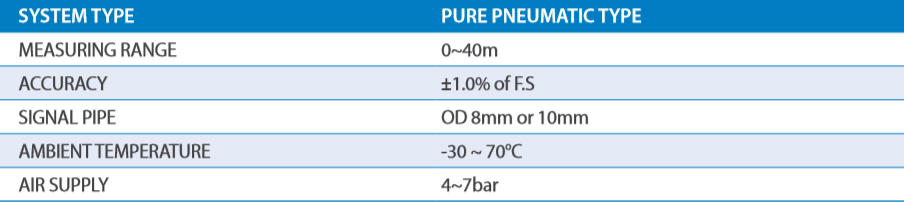

GARGO TANK MONITORING SYSTEM - LEVEL CARGO-BAL-2000 ( PURE PNEUMATIC TYPE )

GENERAL INFORMATION

BALLAST TANK & DRAFT LEVEL GAUGING SYSTEM is designed to measure the level of ballast tanks, draft and fuel oil tanks of ships. This system uses the pneumatic type level sensor and is used for measuring various kinds of tanks.OPERATION PRINCIPLE & SYSTEM COMPOSITION

BAL-2000 is composed of an air purge unit, a dual check valve, a flow regulator, a 3-way cock valve, a gauge saver and an analog indicator for each tank. The operating principle is based on the measuring the hydrostatic head of the liquid by providing constant low flow of air into a probe, called as sounding pipe, which opens at the bottom. When a light quantity of air is discharged through the purge mouth at the tank bottom, an air pressure corresponding to the liquid level will be built up in the sounding pipe. If the specific gravity of the liquid is known and pressure in the sounding pipe is measured, it is possible to calculate the distance from the pipe opening to the surface by means of the above expression. The pressure is read on the indicator graduated scale in meters or volume or percent of full tank.- FEATURE & ADVANTAGE

- Simple principle and structure

- Easy maintenance

- Relatively inexpensive price

- No electrical equipment – No Ex-proof equipment

- APPLICATION

- Ballast tank remote reading

- Draft remote reading

- Fuel oil tank remote reading

- LEVEL INDICATOR

- MODEL : PLG-200

- Dimension : 144 x 144 x 55.5mm

- Accuracy : 1.5% of F.S

- Working Temperature Gas : -20 ~ 65°C

- GAUGE SAVER

- MODEL : GSU-200

- Body material : AL

- Accuracy : 1.5% of F.S

- Differential : Below 0.01 kg/㎠

- 3 WAY COCK

- MODEL : MCK-200

- Fluid : Air/Inert Gas

- Operating Pressure : 0 to 1.0 MPa

- Ambient and Fluid Temperature : -5 ~ 60°C (No Freezing)

- Effective Area : 19 ㎟

- Lubrication : Not Required (Use Turbine Oil Glass 1 ISO VG32, lf Lubricated)

- Port Size : 1/4

- FLOW MODULATOR

- MODEL : FRU-200

- Body material : AL

- Air supply : 4.5 kg/㎠

- Flow rating : 10~80 NL/H

- Blowing pressure : 4.5 kg/㎠

- DUAL CHECK VALVE

- MODEL : DCV-200

- Body material : Nabal brass / SUS316

- Connection size : JIS 5K or 10K Flange

- Working pressure : Max 10 kg/㎠

COMPONENTS / OUTLINE

TECHNICAL SPECIFICATION

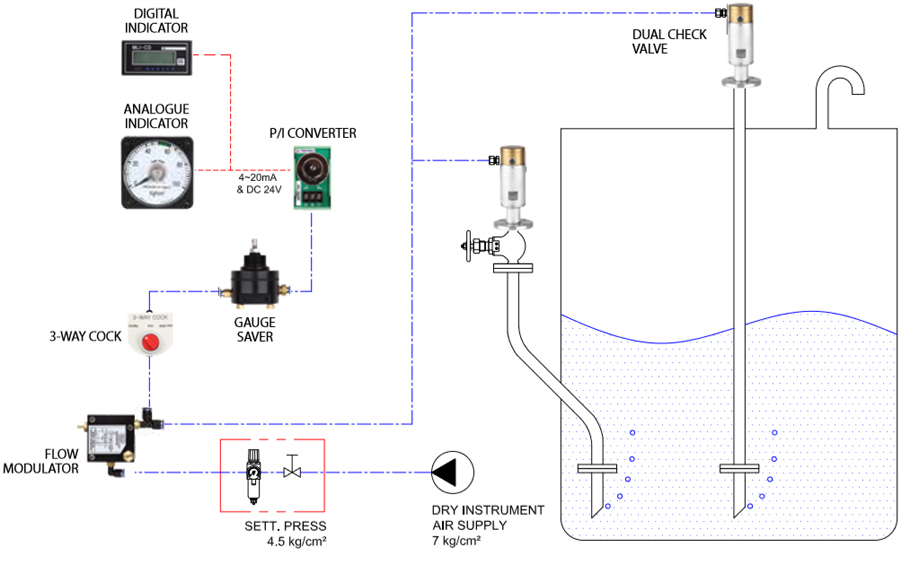

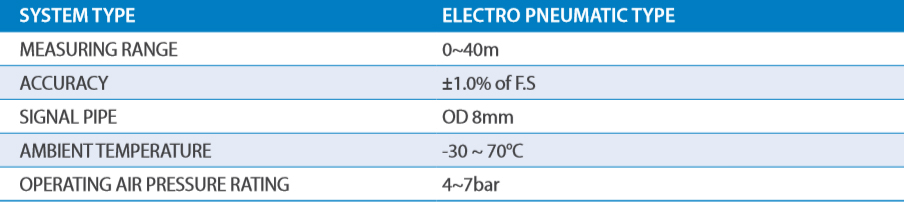

GARGO TANK MONITORING SYSTEM - LEVEL BAL-2000 ( ELECTRO PNEUMATIC TYPE )

GENERAL INFORMATION

BALLAST TANK & DRAFT LEVEL GAUGING SYSTEM is designed to measure the level of ballast tanks, draft and fuel oil tanks of ships. This system uses the pneumatic type level sensor and is used for measuring various kinds of tanks.OPERATION PRINCIPLE & SYSTEM COMPOSITION

BAL-2000 is composed of an air purge unit, a dual check valve, a flow regulator, a 3-way cock valve, a gauge saver, an analog indicator, P/I converter and a digital indicator for each tank. The basic operating principle is same as PURE PNEUMATIC TYPE, but this system uses P/I converter and digital indicator additionally to indicate the level digital figure.- FEATURE & ADVANTAGE

- Simple principle an structure

- Easy installation and maintenance

- Relatively inexpensive price

- No electrical equipment – No Ex-proof equipment

- Possible for digital indicating by P/I converter

- APPLICATION

- Ballast tank remote reading

- Draft remote reading

- Fuel oil tank remote reading

- DIGITAL INDICATOR

- MODEL : MAG-201

- Input : 4~20mA

- ANALOGUE INDICATOR

- MODEL : MAG-200

- Input : 4~20mA

- Internal resistence : 10 ohm

- Indicating accuracy : High value of ±1.0 OF F.S

- Dimension : 110x110mm

- P/I CONVERTER

- MODEL : PHDH-200

- Excitation(Calibration Voltage) : DC 24V

- Excitation : DC 11~28V

- Output : 4~20mA

- Accuracy(RSS) : ±0.5% OF F.S

- Compensated Temerature Range : 0~70 °C

- Operating Temperature Range : -20~80 °C

- Thermal Effect on Zero : 0.03% F.S/ °C

- Thermal Effect on Span : 0.03% F.S/ °C

- FLOW MODULATOR

- MODEL : FRU-200

- Body material : AL

- Air supply : 4.5 kg/㎠

- Flow rating : 10~80 NL/H

- Blowing pressure : 4.5 kg/㎠

- DUAL CHECK VALVE

- MODEL : DCV-200

- Body material : Nabal brass / SUS316

- Connection size : JIS 5K or 10K Flange

- Working pressure : Max 10 kg/㎠

COMPONENTS / OUTLINE

TECHNICAL SPECIFICATION

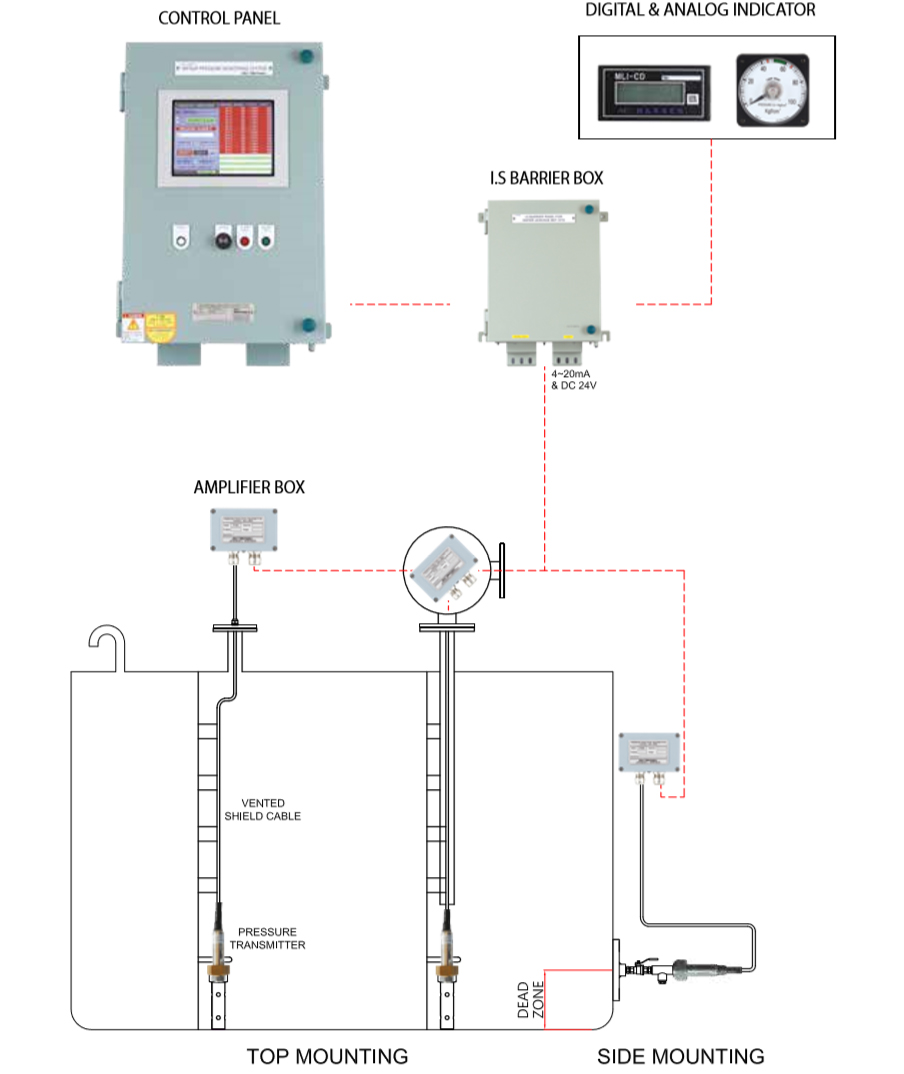

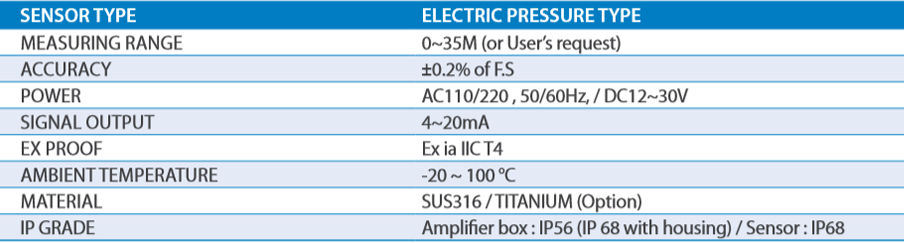

GARGO TANK MONITORING SYSTEM - LEVEL BAL-2000 ( ELECTRIC PRESSURE TYPE )

GENERAL INFORMATION

BALLAST TANK & DRAFT LEVEL GAUGING SYSTEM is designed to measure the level of ballast tanks, draft and fuel oil tanks of ships. This system uses the electric pressure transmitter and is used for measuring various kinds of tanks.OPERATION PRINCIPLE & SYSTEM COMPOSITION

BAL-2000 is composed of pressure transmitters, a control panel, indicators and barriers. The electric pressure type level sensor is to detect changes of the pressure and output the level of tanks as 4~20mA signal when the pressure of the object affects to it.

- FEATURE & ADVANTAGE

- Easy installation and replacement of sensor

- Proper price

- Simple structure

- Integrated monitoring by LCD display

- High accuracy for measuring

- Excellent stability

- APPLICATION

- Ballast tank remote reading

- Draft remote reading

- Fuel oil tank remote reading

COMPONENTS / OUTLINE

TECHNICAL SPECIFICATION

COPYRIGHT © 2018 EHENG Co.,Ltd. ALL RIGHTS RESERVED. [Login]

COMPANY INFO

SERVICE SCOPE

SUPPORT

CONTACT US